Open Gear Control

In the businesses of cement and mining industries where open gear systems are used, we ensure the reliable operation of equipment throughout their service life by providing on-site gear inspection services conducted by our expert engineers.

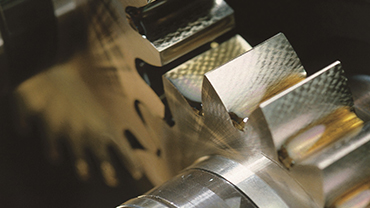

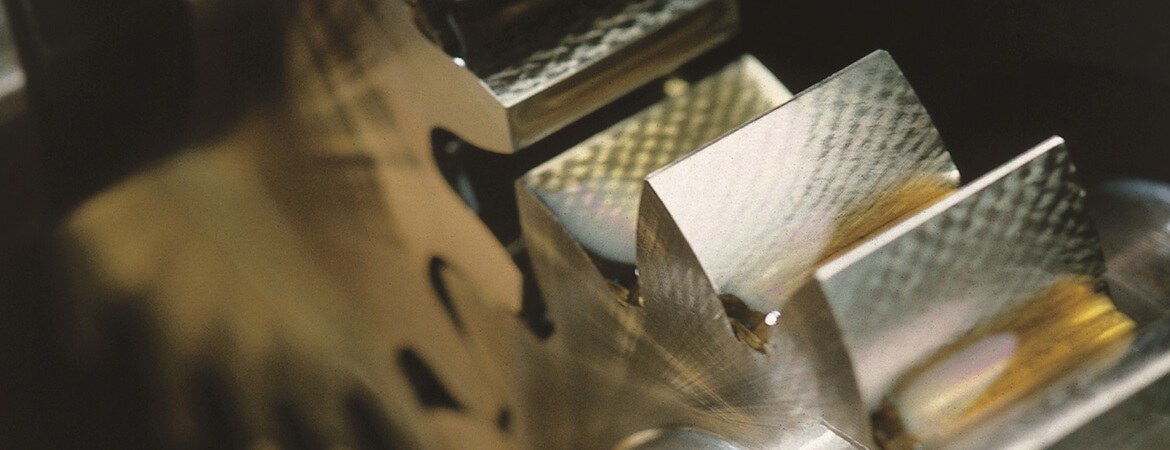

Open gears operate under high speeds and vibrations in mill applications and under high pressure, temperature and load in kiln applications.

In order for the businesses to continue their production with high efficiency, the equipment must function properly. Proper lubricant, proper lubricant quantity and correct application of the lubricant play important roles in trouble-free functioning. To ensure proper and reliable operation of equipment throughout their service life, we provide the required technical support truly via regular on-site open gear inspection services provided by our team of expert engineers.

While making observations about general operating status of lubricants and equipment, we detect the amount of wear on load-carrying-gear surfaces, and check out parameters such as spray pattern, lubricant consumption, temperature and vibration.

Thereby, we help you optimize the quantity of lubricant used, extend lubrication intervals, and increase equipment efficiency.

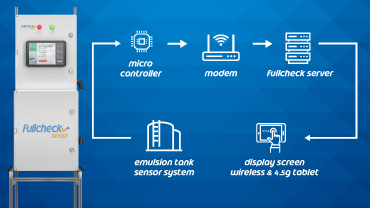

In addition to these, we record the data collected from the field into the FUCHS LUBRICANT INSPECTOR system, a modern documentation system, and prepare comprehensive open gear reports for our business partners.

FUCHS LUBRICANT INSPECTOR reports enable us to be able to access all past measured data of the equipment at any time, and detect even the slightest changes through trend analyses, and thereby, we have the opportunity prevent major breakdowns.