Technical Videos

How to Choose Right Engine Oil for Your Vehicle?

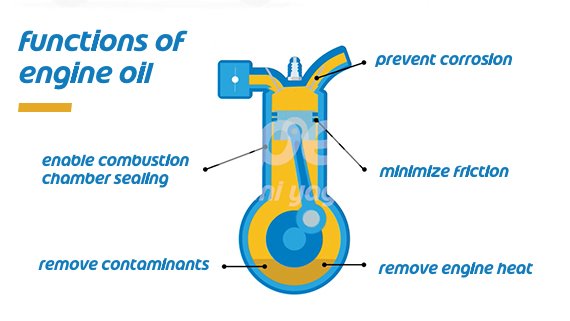

It is very important to use the right engine oil to get the best performance from your vehicle. So, what is the right oil? How to choose?

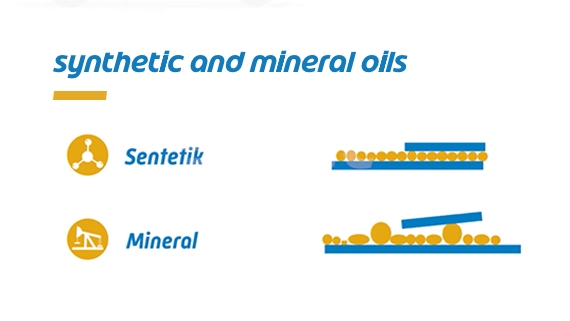

Synthetic and Mineral Oils

Lubricants are produced as synthetic or mineral according to the raw material selection and production technologies. So, what are the differences between these oils?

What is Turbocharger?

High-capacity vehicles and engines that can produce more power with less fuel consumption are needed in the transportation, and logistics sectors. How do Turbocharger systems, which are produced to develop this need, work?

Engine Oils for LPG Powered Vehicles

Do you know the importance of the engine oil properties used in LPG powered vehicles for the overall performance and durability of the engine?

Engine Oil Impact on Fuel Economy

Learn about the fuel economy which shows the relationship between a vehicle's travelled distance and the spent fuel.

Oil Drain Interval for Long Life in the Engine

What are the factors affecting the oil drain interval for a longer engine life?

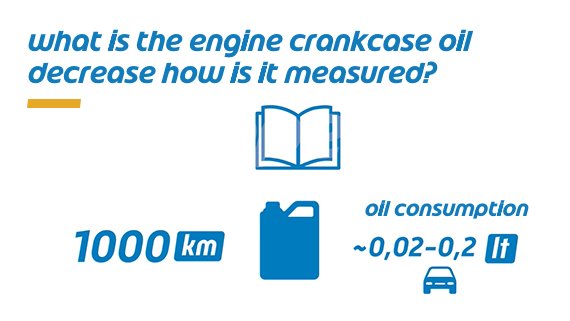

What is the Engine Crankcase Oil Decrease How is it Measured

What are the factors affecting oil loss, how is it measured?